For edible oil production

Candle filter is a self-cleaning filter specially designed for solid-liquid separation, typically used for the clarification and recovery of liquids with low solids content from 5 % to less than 1 % or even trace amounts of solids.

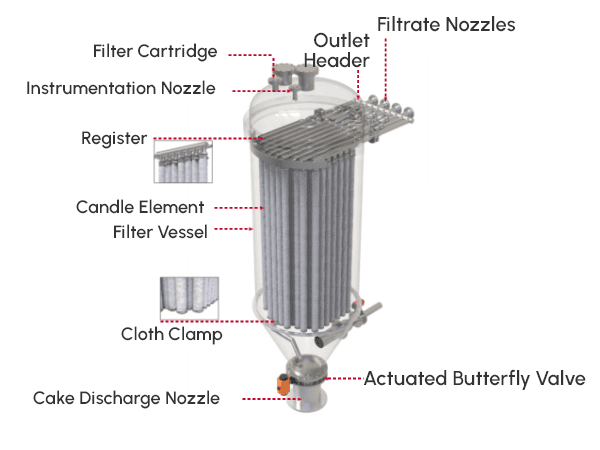

Candle filter is composed of a filter housing, filter bags, filter elements, registers, a computer control system, accessories, etc.

The filter housing is provided with instrument connection nozzle, air vent, inlet nozzle, discharge nozzle, inspection hole, etc.

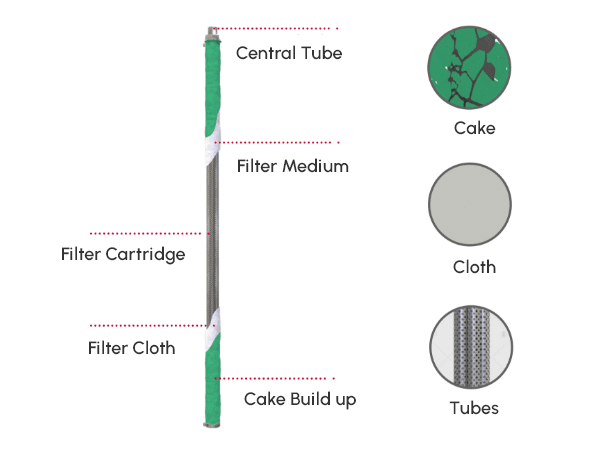

Candle filter consists of multiple combined filter elements inside. Every filter element is composed of 6 porous metal tubes and a central tube and then covered with a filter bag. The filter bag is selected according to the characteristics of the raw material liquid. Filter aids are required when filtering some special raw material liquids, such as activated carbon, diatomaceous earth, etc. Filter elements are used to support filter bags, and all filter elements are connected to the register at the top of the filter.

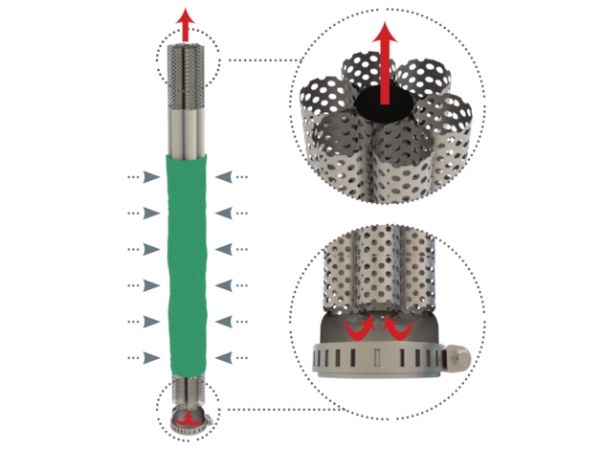

Filter aids are added into the liquid to be filtered. The liquid flows through the filter bag and flows from porous metal tubes to the central pipe. Filter bags are attached to the outer surface of filter elements due to pressure. Due to its unique structure, it offers an enlarged filter area. As the liquid circulates, a porous filter cake (precoating) is formed on the surface of the filter bag. The filter cake makes the filtrate get further filtration.

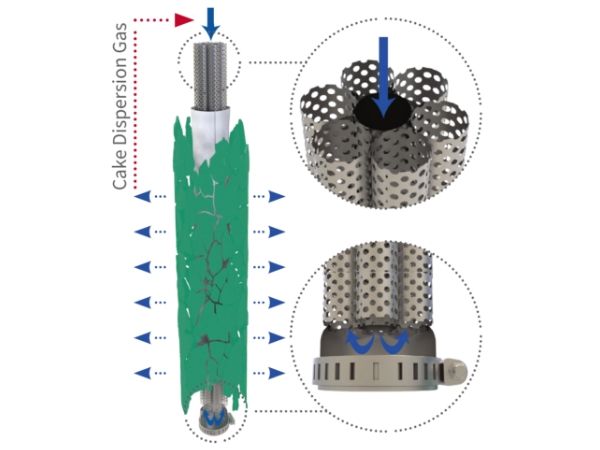

When the filter cake accumulates to a certain thickness and the differential pressure reaches the preset value, the control system gives a signal, and the filter stops feeding and empties the residual fluid. The filter is then filled with hot gas (air, nitrogen, steam) from the overflow vents at the top of the filter into the filter, the filter cake outside the filter bag is dried by the gas.

When the filter cake is dried, inject gas from the register for back flushing, the filter bag expands and the dried filter cake falls off and is discharged from the cake drainage nozzle.

When the filter cake is discharged, the nozzle on the register sprays liquid to clean these filter elements and then enters the next filtration cycle.

Candle filters are mainly used to purify liquids with low solid content and recover expensive materials from them. They are widely used in the following industries.

For edible oil production

For oil & gas industry

For lithium production