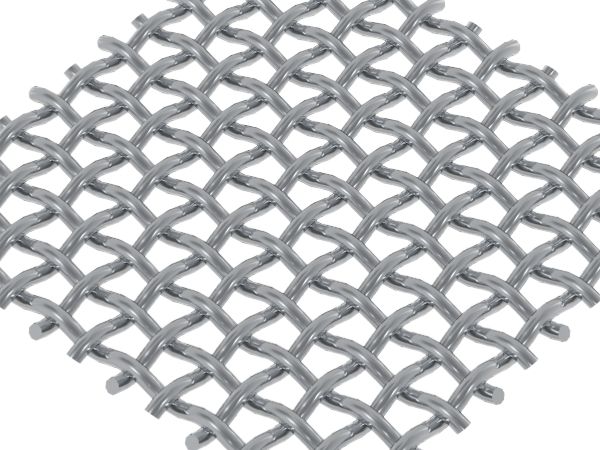

Plain weave

Filter leaves are filter elements installed in pressure leaf filters. Generally, 10 to 60 filter leaves are stacked inside a vertical or horizontal pressure leaf filter and filter leaves are the heart and the most critical part of pressure leaf filters.

Stainless steel woven mesh for filer leaves generally adopts plain weave, plain dutch weave, reverse plain dutch weave and reverse dutch twill weave. Generally drain mesh and supporting mesh adopts plain weave, fine mesh adopts plain weave, plain dutch weave, reverse plain dutch weave or reverse dutch twill weave.

Plain weave

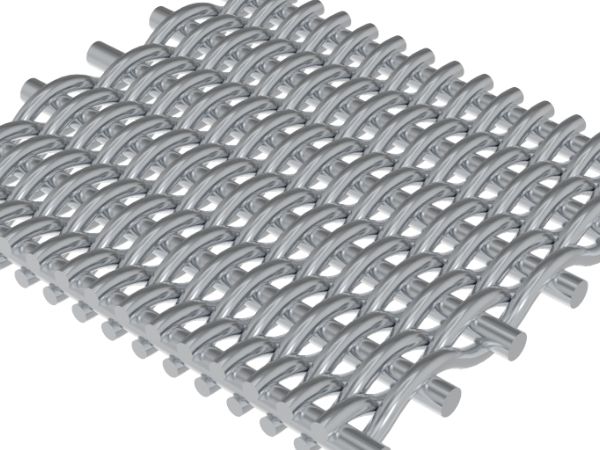

Plain dutch weave

Reverse plain dutch weave

Reverse dutch twill weave

| Construction | Mesh | Wire Thickness (mm) | Aperture (μm) |

|---|---|---|---|

| 1 layer of drainage mesh | Plain weave, 4 × 4 | 1.6 | 4750 |

| 2 layer of support mesh | Plain weave, 8 × 8 | 0.7 | 2470 |

| 2 layer of fine filter mesh | Plain weave, 60 × 60 | 0.18 | 240 |

| Plain dutch weave, 24 × 110 | 0.54 | 152 | |

| Plain dutch weave, 24 × 128 | 0.58 | 75 | |

| Plain dutch weave, 30 × 150 | 0.53 | 85 | |

| Reverse plain dutch weave, 132 × 32 | 0.77 | 91 | |

| Reverse dutch twill weave, 325 × 40 | 0.73 | 100 |

Pressure leaf filters are a closed type automatic solid-liquid separation device and can work with variety of filtering aids. They apply to decolorization and filtration, pharmaceutical oil filtration, crystallization separation process, etc. in the production of oil and grease and chemicals and are mainly used in the following industries.

For vegetable oil primary processing

For oil refinery

For sulfuric acid production

For vegetable oil primary processing

For engine oil purification

For sulfuric acid production