Sewn filter bag

Filter bags are one of the most common and economical filter elements in liquid filtration. They are installed in bag filters for high flow liquid filtration. We offer felt filter bags, monofilament mesh filter bags, multifilament mesh filter bags and stainless steel filter bags for you to choose from.

Felt filter bags are manufactured from polypropylene and polyester needle felt materials and provide the most economic value and reliable choice for a wide range of filtration applications.

Monnofilament mesh filter bags are woven from single-fiber threads. Bags made from this material have excellent strength and are washable.

Multifilament mesh filter bags are woven from monfilament threads made of twisted smaller fibers. Bags made from this material are low cost and disposable and their filtration efficiency is lower than those of monnofilament mesh filter bags.

Stainless steel filter bags are made of stainless steel woven cloth. Compared with non-woven filter bags, stainless steel filter bags have a longer service life and better corrosion resistance.

Sewn filter bag

Weld filter bag

Sewn metal ring sealed filter bag

PP ring sealed filter bag

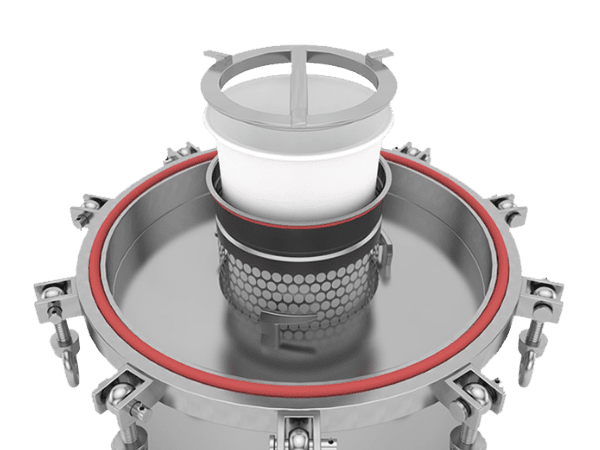

Place the filter bag into the support basket. Fluid flows into the filter from the inlet and flows out of the outlet after in-house filtration. Impurities are trapped in the filter bag. Filter bags need to be replaced after a period of use.

Filter bags are made from a variety of materials, you may choose corresponding filter bags based on the chemical compatibility and temperature of the materials.

| Material | Max. Operating Temperature (°C) | Aromatic Solvents | Aliphatic Solvents | Acid | Strong Acid | Base | Strong Base | Vegetable Oil/Animal Oil |

|---|---|---|---|---|---|---|---|---|

| PP | 90 | - | √ | √ | √ | √ | √ | √ |

| Polyester fiber | 150 | √ | √ | √ | √ | √ | - | √ |

| Nylon | 135 | √ | √ | - | - | √ | √ | - |

| PTFE | 260 | - | - | √ | √ | √ | - | √ |

| Note: Chemical compatibility refers to the harmonious conjugation of two substances when they come into contact with each other. When mixed, substances are considered compatible if they have no physical or chemical changes; they are considered incompatible if they undergo physical or chemical changes. | ||||||||

| Size Code | Diameter | Bag Length | Flow Rate | Filter Surface Area | Inflated Volume |

|---|---|---|---|---|---|

| 01 | 7" (177.8 mm) | 17" (431.8 mm) | 20 m3/h | 0.25 m2 | 8.0 L |

| 02 | 7" (177.8 mm) | 32" (812.8 mm) | 40 m3/h | 0.50 m2 | 17.0 L |

| 03 | 4" (101.6 mm) | 8" (203.2 mm) | 6 m3/h | 0.09 m2 | 1.30 L |

| 04 | 4" (101.6 mm) | 14" (355.0 mm) | 12 m3/h | 0.16 m2 | 2.50 L |

| 05 | 4" (101.6 mm) | 20" (508.0 mm) | 18 m3/h | 0.20 m2 | 3.80 L |

Bag filters are mainly used to remove trace fine impurities from liquids and are widely used in the following industries.

For paint production water supply filtration systems

For resin production

For beer brewing