For paint production water supply filtration systems

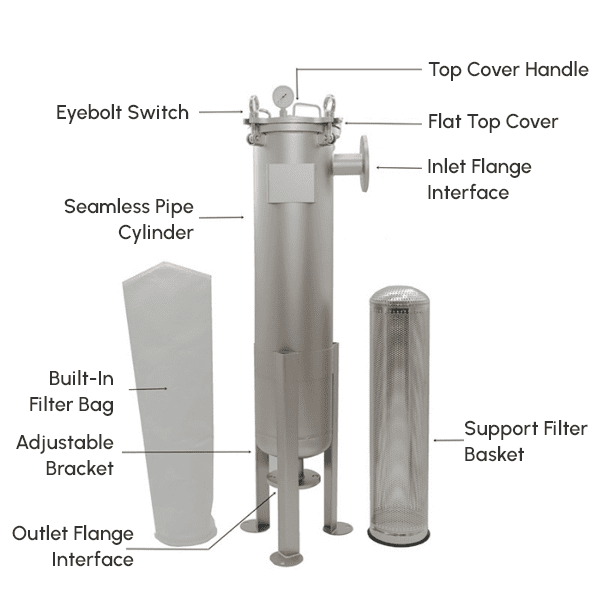

Single bag filter consists of a filter housing, a support basket and a filter bag and is suitable for solid filtration applications at low flow velocity range. In addition, we also offer multi bag filters and duplex bag filters to meet your diversified filtration demands.

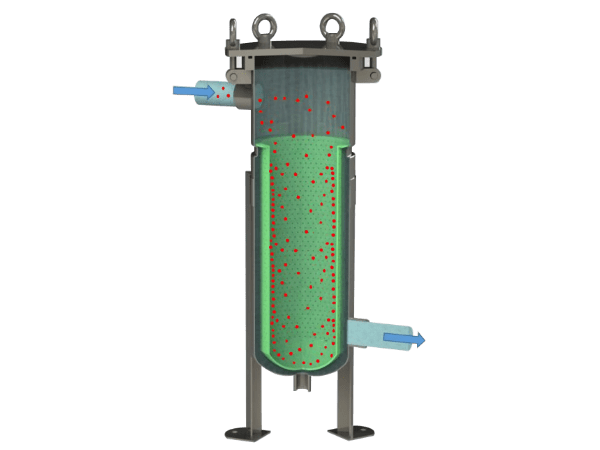

The position of the single bag filter inlet is higher than that of the filter bag. Filter medium flows into the filter bag from the inlet. After filtration, the impurities are trapped in the filter bag, and the clean filtrate flows out from the outlet along the fixed metal basket wall.

The filter bag needs to be replaced when the impurities on the filter bag build up into a filter cake and the differential pressure reaches 0.05-0.1 MPa. When replacing the filter bag, the filter system must be shut down for a period of time, open the pressure relief valve and filter cover, and reinstall the filter after replacing the filter bag. Filter bags can be reused after cleaning, but need to be replaced when damaged to a certain extent. Filter bags can be reused after cleaning, but need to be replaced when being damaged to a certain extent.

Bag filters are mainly used to remove trace fine impurities from liquids and are widely used in the following industries.

For paint production water supply filtration systems

For water treatment

For automobile flushing water filtration