For fiber filtration

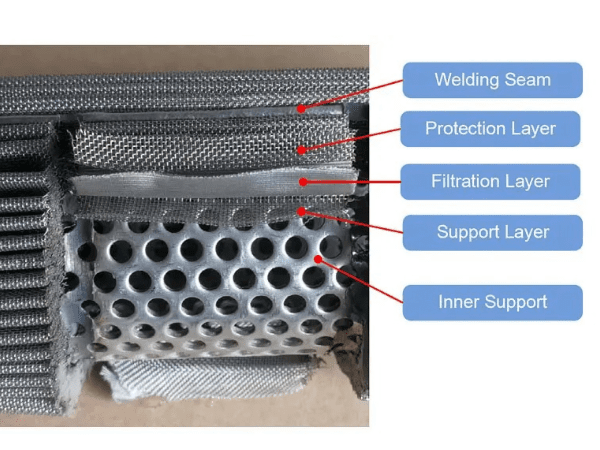

Stainless steel pleated cartridge is made of stainless steel woven mesh or stainless steel sintered felt after pleating and welding. It is generally installed in melt filters to remove impurities from polymer melts in chemical fiber, textile and plastics industries, therefore, it is also known as polymer candle filter or polymer melt candle filter.

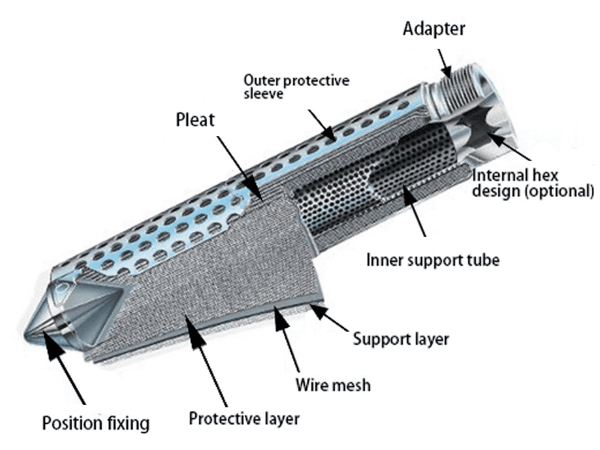

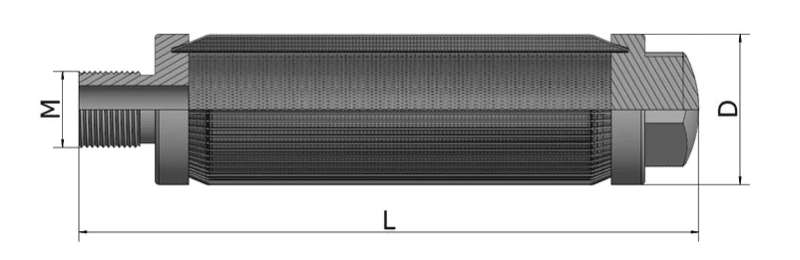

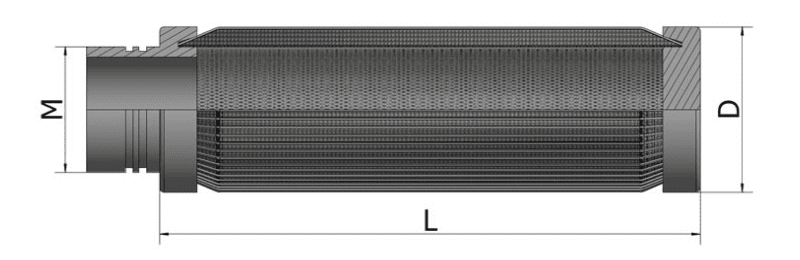

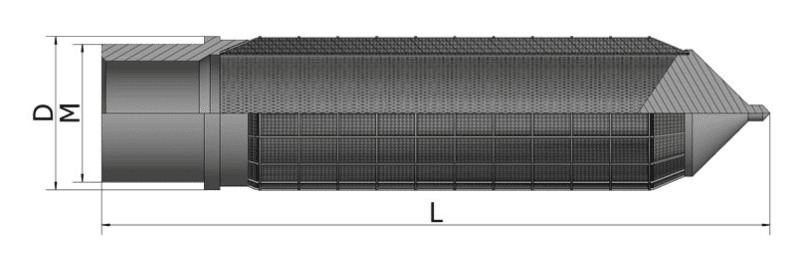

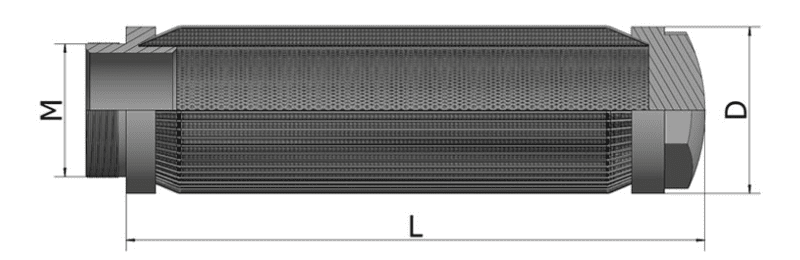

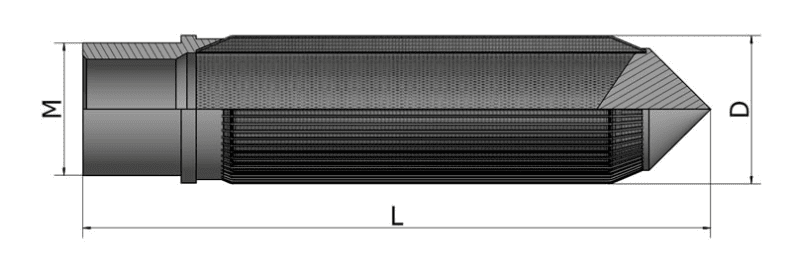

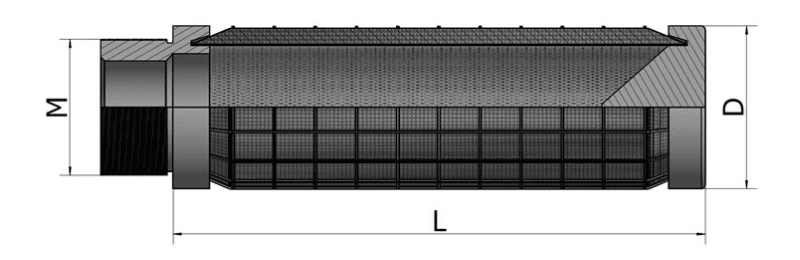

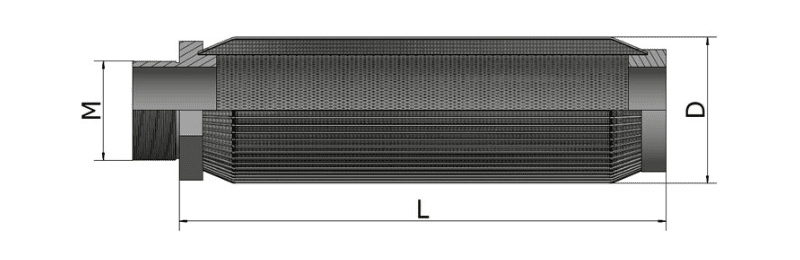

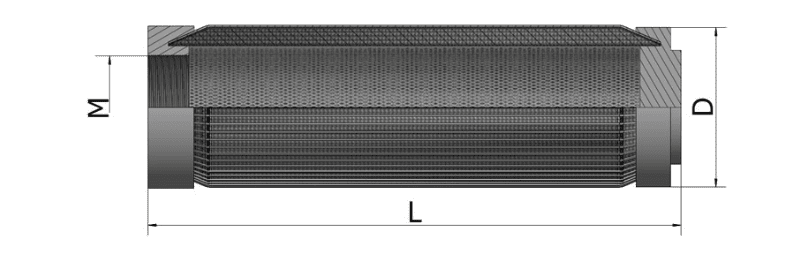

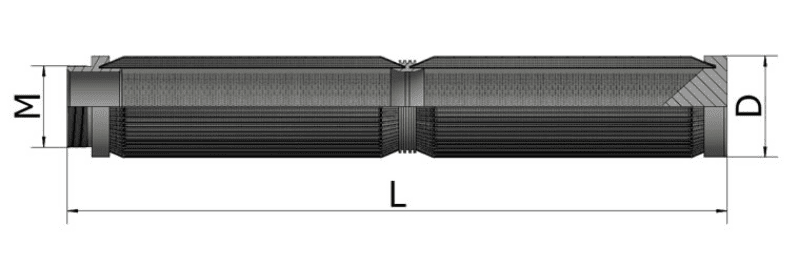

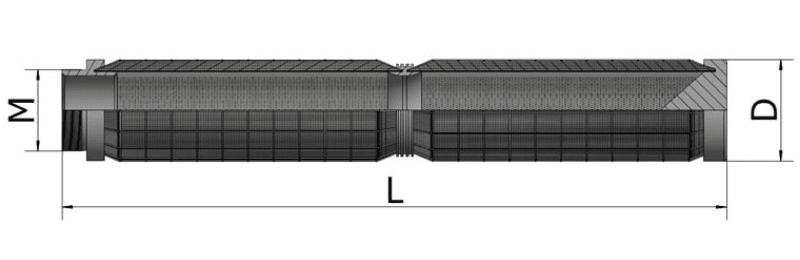

Stainless steel pleated cartridge consists of a position fixing, a pleated layer (protective layer, wire mesh support layer), an inner support tube, an outer protective sleeve and an adapter.

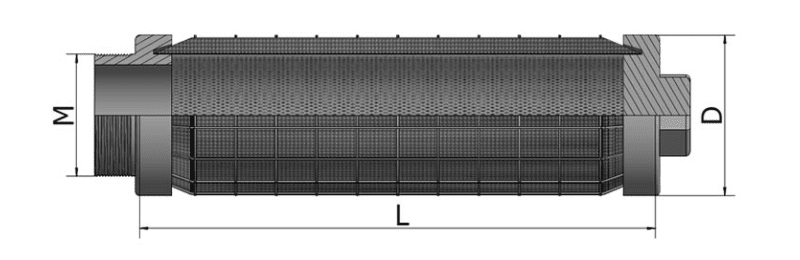

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-86/200 | 200 | 86 | M65 × 2P | 0.2 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-86/350 | 350 | 0.35 | ||||

| SSPC-86/500 | 500 | 0.5 | ||||

| SSPC100/800 | 800 | 100 | M80 × 2P | 1 |

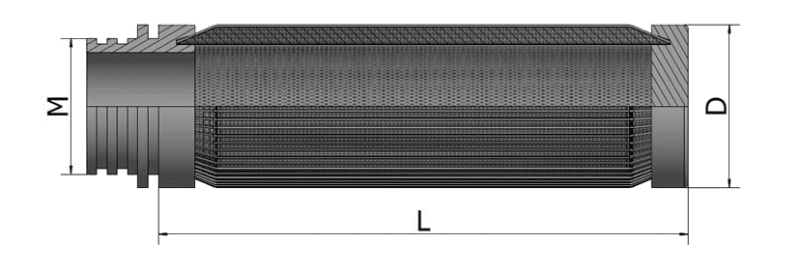

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-65/250 | 250 | 65 | 226, 223, 220, 215 | 0.135 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-65/500 | 500 | 0.38 | ||||

| SSPC-70/750 | 750 | 70 | 0.42 | |||

| SSPC-70/750 | 750 | 70 | 0.6 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-35/102 | 102 | 35 | M18, M20 × 2.5, M20 × 1.5, NPT1", 3/4-16 | 0.026 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-35/207 | 207 | 0.07 | ||||

| SSPC-35/210 | 210 | 0.07 | ||||

| SSPC-35/242 | 242 | 0.08 | ||||

| SSPC-35/425 | 425 | 0.15 | ||||

| SSPC-35/485 | 485 | 0.2 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-62/180 | 180 | 62 | G1" | 0.09 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-86/254 | 254 | 86 | G2" | 0.17 | ||

| SSPC-86/381 | 381 | 0.2 | ||||

| SSPC-86/508 | 508 | 0.27 | ||||

| SSPC-86/760 | 760 | 0.58 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-60/1432 | 1432 | 60 | 2" × 12UN-2A | 1.015 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-60/1241 | 1241 | 0.98 | ||||

| SSPC-60/1025 | 1025 | 0.81 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| inch | inch | m2 | μm | |||

| SSPC-1.75/16.31 | 16.31 | 1.75 | 1.25"-12UNF-2A | 0.2 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-1.75/18.63 | 18.63 | 0.35 | ||||

| SSPC-1.75/31 | 31 | 0.5 | ||||

| SSPC-1.75/47 | 47 | 1 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-45/200 | 1432 | 45 | 1.25"-12UNF, 2"-12UN | 1.015 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-45/800 | 1241 | 0.98 | ||||

| SSPC-57/1023 | 1025 | 57 | 0.81 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-46/965 | 965 | 46 | 1.25"-12UN | 0.52 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-50/1020 | 1020 | 50 | M42 × 2P | 0.62 | ||

| SSPC-60/1020 | 1020 | 60 | M52 × 2P | 0.8 | ||

| SSPC-60/1210 | 1210 | 1 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-50/275 | 275 | 50 | M30 × 1.5P | 0.18 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-50/525 | 525 | 0.33 | ||||

| SSPC-50/870 | 870 | 0.54 | ||||

| SSPC-50/1395 | 1395 | 0.8 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-60/400 | 400 | 45 | M33 × 1.5P, M33 × 2P | 0.4 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-60/500 | 500 | 0.5 | ||||

| SSPC-60/1000 | 1000 | 57 | 1 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-62/1195 | 1195 | 62 | M36 × 2P | 0.6 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-62/1395 | 1395 | 0.7 |

| Model | L | D | M | Filter Area | Filter Rating | Filter Media |

|---|---|---|---|---|---|---|

| mm | mm | m2 | μm | |||

| SSPC-55/1245 | 1245 | 55 | M33 × 2P | 0.91 | 3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 | Stainless steel sintered fiber felt, stainless steel wire cloth |

| SSPC-55/1247 | 1247 | 0.91 | ||||

| SSPC-55/1347 | 1347 | 0.95 | ||||

| SSPC-55/1350 | 1350 | 0.95 |

Stainless steel pleated cartridges are mostly used in melting filters for high-temperature and high-pressure polymer processing and are widely used in the following industries.

For fiber filtration

For non-woven fabric production

For plastic recycling and granulation