End cap connections

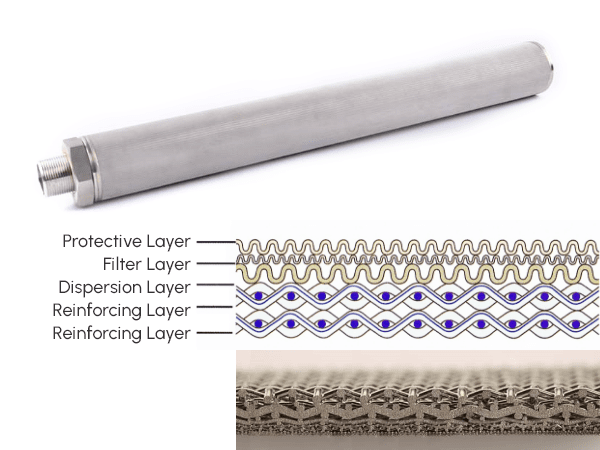

Sintered mesh filter cartridge is constructed from 5 layers of stainless steel wire sintered by high temperature vacuum, argon arc or plasma welding.

Sintered mesh filter cartridge generally adopts standard 5-layer sintered wire mesh laminate as the filter medium.

End cap connections

Sintered mesh filter cartridges are suitable for filtering high temperature and acid-base environments and are widely used in the following industries.

For catalyst recovery

For pharmaceutical water filtration

For beer water filtration