With a lower support frame

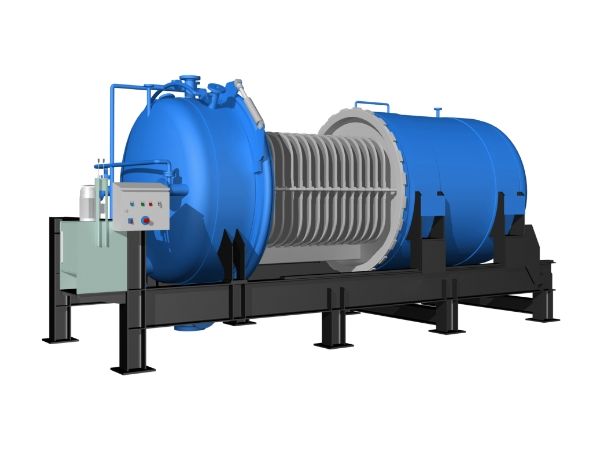

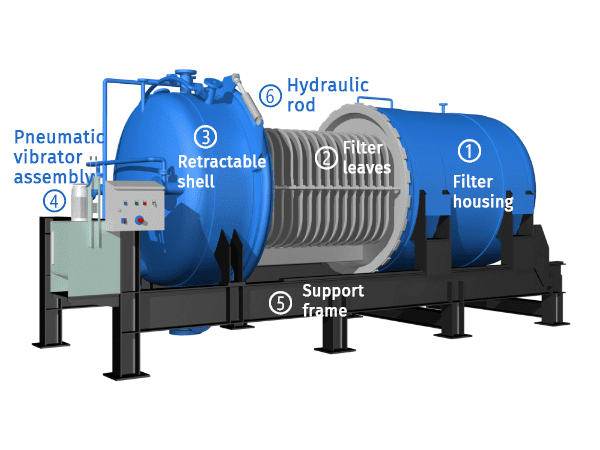

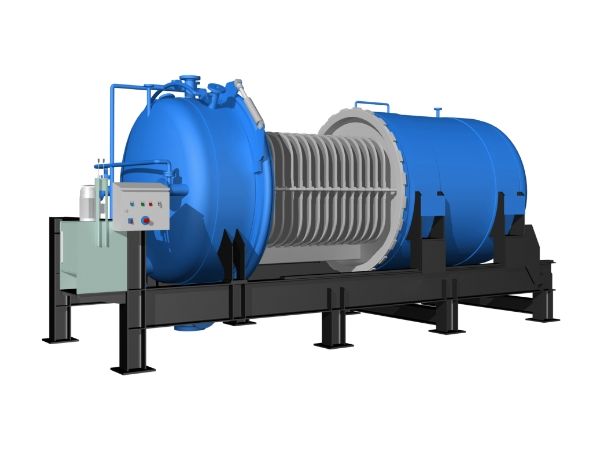

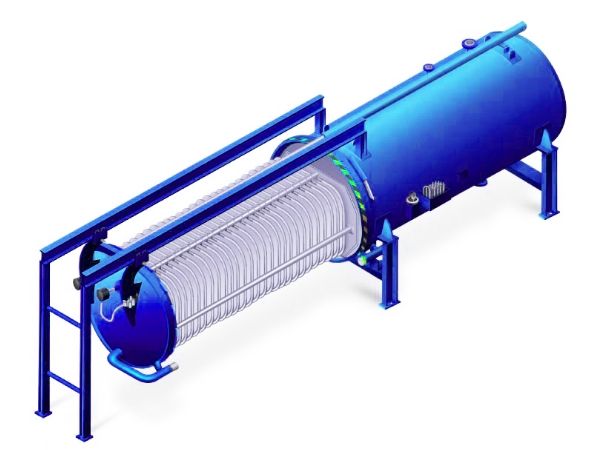

Horizontal pressure leaf filters are your perfect choice for batch processing applications requiring high flow rates with small solids removal. As being placed horizontally, it takes a larger footprint than that of vertical pressure leaf filter. It is widely used in edible oil industry.

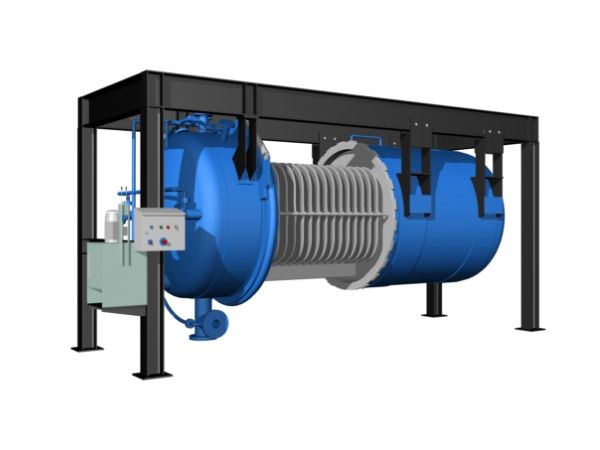

Horizontal pressure leaf filter (shell retraction or bundle retraction) consists of a filter housing, filter leaves, a pneumatic vibrator assembly, a support frame and a hydraulic power back for bonnet ring opening/closing and shell or bundle retraction.

Horizontal pressure leaf filter shells are divided into the following 3 types according to how it is opened.

With a lower support frame

With a retractable bundle

With an overhead suspension frame

When filter cake needs to be recycled or disposed as solids, you may choose dry cake discharge, for example, sugar, cocoa or edible oil filtration, activated carbon removal, molten sulphur filtration or catalyst recovery. Compressed air, inert gas or steam is commonly used for cake drying before discharging.

If the cake formation is too low for dry discharge, the disposal is cheap (regeneration for wet discharge is shorter) or the cake needs to be transported via a pump, you may choose wet cake discharge, for example, saline water filtration.

| Model | Filter Area | Cake Volume | Filter Leaves |

Filter Volume | Leaf Spacing |

Floor Space | Height | Empty Weight |

Feed Connections |

|---|---|---|---|---|---|---|---|---|---|

| m² | dm³ | dm³ | mm | mm | mm | kg | |||

| 1 | 5.5 | 165 | 7 | 800 | 100 | 1150 × 2550 | 1800 | 800 | 1 |

| 2 | 9.5 | 285 | 13 | 1100 | 100 | 1150 × 3750 | 1800 | 1100 | 1 |

| 3 | 12.5 | 375 | 8 | 1300 | 100 | 1500 × 2800 | 2000 | 1500 | 1 |

| 4 | 15 | 450 | 10 | 1800 | 100 | 1500 × 3200 | 2000 | 1700 | 1 |

| 5 | 20 | 600 | 14 | 2300 | 100 | 1500 × 4000 | 2000 | 1900 | 1 |

| 6 | 25 | 750 | 17 | 2700 | 100 | 1500 × 4600 | 2000 | 2050 | 2 |

| 7 | 30 | 900 | 20 | 3100 | 100 | 1500 × 5200 | 2000 | 2200 | 2 |

| 8 | 40 | 1200 | 16 | 4400 | 100 | 2000 × 4700 | 2400 | 2500 | 1 |

| 9 | 50 | 1500 | 20 | 5200 | 100 | 2000 × 5500 | 2400 | 2750 | 2 |

| 10 | 60 | 1800 | 24 | 600o | 100 | 2000 × 6300 | 2400 | 2810 | 2 |

| 11 | 70 | 2100 | 28 | 6800 | 100 | 2000 × 7100 | 2400 | 3000 | 2 |

| 12 | 80 | 2400 | 32 | 7600 | 100 | 2000 × 7900 | 2400 | 3250 | 2 |

| 13 | 100 | 3000 | 28 | 11000 | 100 | 2300 × 7200 | 2400 | 6500 | 2 |

| 14 | 125 | 3750 | 35 | 13000 | 100 | 2300 × 8800 | 2800 | 7200 | 2 |

| 15 | 150 | 4500 | 36 | 14000 | 100 | 2600 × 10000 | 2800 | 7800 | 2 |

| 16 | 175 | 5250 | 42 | 16000 | 100 | 2600 × 11200 | 3000 | 8150 | 3 |

| 17 | 200 | 6000 | 48 | 18000 | 100 | 2600 × 12400 | 3000 | 8500 | 3 |

Pressure leaf filters are a closed type automatic solid-liquid separation device and can work with variety of filtering aids. They apply to decolorization and filtration, pharmaceutical oil filtration, crystallization separation process, etc. in the production of oil and grease and chemicals and are mainly used in the following industries.

For vegetable oil primary processing

For engine oil purification

For sulfuric acid production