For vegetable oil primary processing

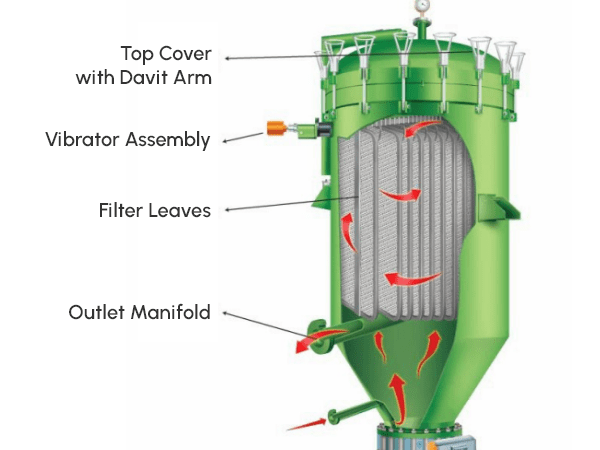

Vertical pressure leaf filters are your ideal choice for batch process applications requiring high flow rates in a small footprint. As a result, it is suitable for places where the space is limited or interrupted flow is expected. In addition, we also offer horizontal pressure leaf filters to meet different industrial demands.

First, precoat is applied before filtering. Agitate precoat tank containing filtrate and filter aid (diatomaceous earth, perlite, etc.) for around 10 minutes. Then, fill the vessel with the mixture, empty all the air, and pressurize the vessel. The precoat runs for 15 minutes at a fluid rate around 30–60 gallons per square foot per hour.

After precoating, slurry is forced through the vessel under pressure. Solid particles are trapped in the precoat, or filter media while clarified liquid flowing out of the filter through the manifold.

Choose whether to dry filter cake as needed. If you need dry cake, compressed air, inert gas or steam is commonly used for cake drying before discharging. After drying, filter cake is discharged by a pneumatic vibrator through a butterfly valve located at the bottom of the filter. Wet cake may be discharged by a pneumatic vibrator or spray nozzle.

When filter cake needs to be recycled or disposed as solids, you may choose dry cake discharge, for example, sugar, cocoa or edible oil filtration, activated carbon removal, molten sulphur filtration or catalyst recovery. Compressed air, inert gas or steam is commonly used for cake drying before discharging.

If the cake formation is too low for dry discharge, the disposal is cheap (regeneration for wet discharge is shorter) or the cake needs to be transported via a pump, you may choose wet cake discharge, for example, saline water filtration.

| Model | Filter Area | Cake Volume | Filter Leaves | Filter Volume | Leaf Spacing | Floor Space | Height | Weight (empty) |

|---|---|---|---|---|---|---|---|---|

| m2 | dm3 | dm3 | mm | mm | mm | kg | ||

| 1 | 1.65 | 35 | 5 | 210 | 70 | 1220 × 1100 | 2110 | 350 |

| 2 | 2.2 | 50 | 5 | 320 | 70 | 1320 × 1300 | 2210 | 400 |

| 3 | 3 | 70 | 3 | 600 | 70 | 1340 × 1540 | 3020 | 550 |

| 4 | 5 | 105 | 5 | |||||

| 5 | 7 | 135 | 7 | |||||

| 6 | 5 | 110 | 5 | 800 | 70 | 1750 × 1090 | 3090 | 650 |

| 7 | 7 | 155 | 7 | |||||

| 8 | 9 | 175 | 9 | |||||

| 9 | 8 | 175 | 7 | 1000 | 70 | 1190 × 1230 | 3190 | 800 |

| 10 | 10 | 220 | 9 | |||||

| 11 | 12.5 | 275 | 11 | |||||

| 12 | 15 | 330 | 9 | 2000 | 70 | 2370 × 1680 | 4000 | 1100 |

| 13 | 17.5 | 385 | 9 | |||||

| 14 | 20 | 440 | 11 | |||||

| 15 | 23.5 | 520 | 11 | 2500 | 75 | 2210 × 2650 | 4100 | 1725 |

| 16 | 25 | 550 | 11 | |||||

| 17 | 27 | 590 | 13 | |||||

| 18 | 30 | 660 | 15 | |||||

| 19 | 30.5 | 670 | 11 | 3600 | 75 | 2900 × 2110 | 4500 | 1980 |

| 20 | 35 | 770 | 13 | |||||

| 21 | 38.5 | 850 | 15 | |||||

| 22 | 42 | 920 | 13 | 4500 | 75 | 3110 × 230 | 4880 | 2300 |

| 23 | 46 | 1010 | 15 | |||||

| 24 | 50 | 1100 | 17 | |||||

| 25 | 55 | 1210 | 15 | 4900 | 75 | 3110 × 2350 | 5180 | 2500 |

| 26 | 60 | 1320 | 17 | |||||

| 27 | 70 | 1540 | 16 | 6300 | 75 | 3770 × 2640 | 5650 | 3200 |

| 28 | 78 | 1720 | 18 | |||||

| 29 | 85 | 1870 | 16 | 8200 | 75 | 3440 × 3890 | 3000 | 4400 |

| 30 | 100 | 2200 | 20 |

Pressure leaf filters are a closed type automatic solid-liquid separation device and can work with variety of filtering aids. They apply to decolorization and filtration, pharmaceutical oil filtration, crystallization separation process, etc. in the production of oil and grease and chemicals and are mainly used in the following industries.

Food & beverage. Edible oil coarse filtration, bleached oil filtration, gelatin, vinegar, starch, sugar juice, sweet water, etc.; beer, juice, wine, milk, etc.

For vegetable oil primary processing

For oil refinery

For sulfuric acid production